Home / All / Decoiler / Hydraulic Decoiler /

[MT-1100F] Hydraulic Uncoiler machine for Sheet Metal Stamping Parts Production

[MT-1100F] Hydraulic Uncoiler machine for Sheet Metal Stamping Parts Production

![[MT-1100F] Hydraulic Uncoiler machine for Sheet Metal Stamping Parts Production](https://icdn.tradew.com/file/201405/1556694/jpg/6840366.jpg?x-oss-process=image/resize,m_pad,l_250/quality,Q_90)

| Categories | Hydraulic Decoiler |

|---|---|

| Brand | HongEr |

| Model | MT-1100F |

| Coil Width | up to 1100mm |

| Coil Weight | up to 5000kg |

| Coil Thickness | 0.1-3.2mm |

| Coil I.D. | 450-530mm |

| Coil O.D. | up to 1200mm |

| Expansion | Hydraulic |

| Coil Car | Included |

| Pressing Arm | Pneumatic |

| Decoiler Speed | 16m/min |

| Update Time | Jul 27,2024 |

Detail Information

Applicable Material

Material thickness

0.1 mm to 3.2 mm

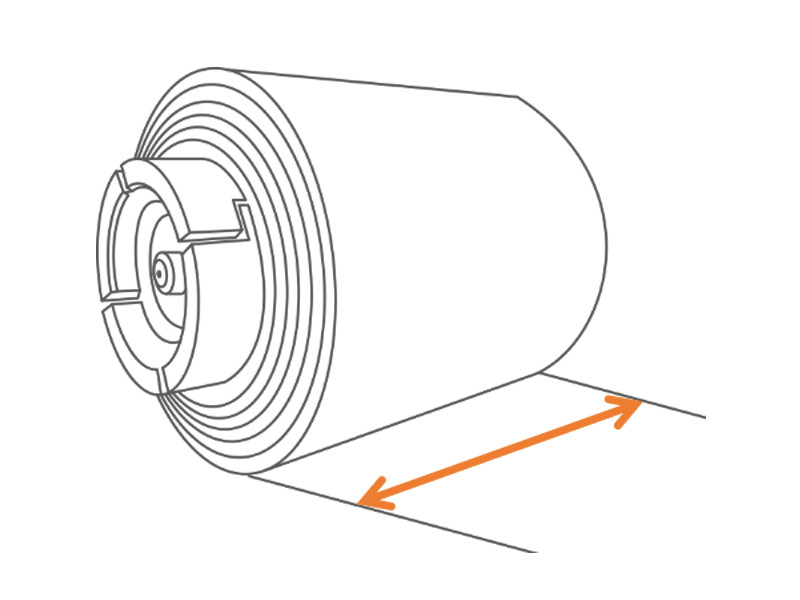

Strip Width

20 mm to 1100 mm

Coil Weight

Up to 5000kgs

Product Description

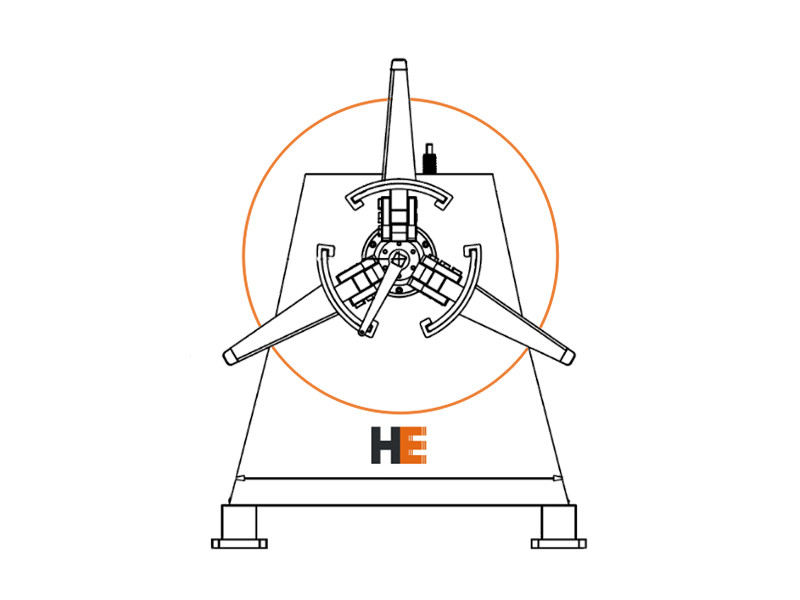

MT-1100F Hydraulic Decoiler for Press Feed Sheet Coil Processing

Operation: Motorized

Mandrel Expansion: Hydraulic

Application: Press Feed

Decoiling speed: 16 m/min

Coil Car: Included

Suitable for most kind of coil material, such as CR Steel, HR Steel, Galvanized steel, Stainless steel, Pre-painted, Aluminum, Cooper etc.

Specification of Decoiler

Model |

MT-1100 |

Coil Width |

1100mm |

Coil Thickness |

0.1 mm - 3.2mm |

Coil I.D. |

450-530 mm |

Coil O.D. |

1200 mm |

Coil Weight |

5000 kgs |

Expansion | Hydraulic Expanion |

Pressing Arm | Pneumatic Type Pressing Arm |

Inverter | Delta, Taiwan |

Speed |

16 m/min |

Coil Car | Included |

Packing

Machine wrapped up with plastic film

Fix decoiler machine into wooden case

Delivery packages to port

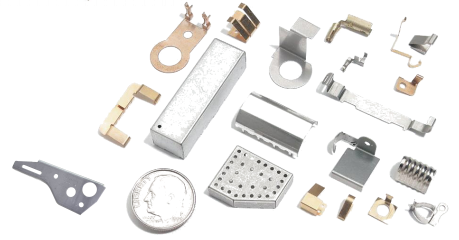

Application

Most of our decoilers are used in press feeding lines.

HongEr also provide customization decoilers for cut to length line,

coil slitting line,

roll forming line.

Model Selection

HongEr has many different kinds of decoilers for all types of sheet metal. We have over 16 years of experience.

When considering a sheet metal decoiler, there are several basic information you should take into account:

1. The thickness of the metal sheet

2. The width range of metal sheet

3. The maximum weight of metal coil

4. The metal coil inside diameter

5. The metal coil outside diameter

6. Sheet metal Decoiling speed request

All the above info influences the decoiler configuration and capabilities required for a successful installation.

General configruation for press feeding line

Hydraulic Decoiler with Pressing Arm to Indonesia

Hydraulic Decoiler with Pressing Arm, Supporting Arm and Coil Car to Mexico

For more information, please contact: export@he-machine.com

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Send the inquiry, Honger is ready to design the best machine solution for you!

navigation

Contact Person

- Name:

- Fenny Ye

- Tel:

86-755-28372363

86-755-84829280

- Email:

- export@he-machine.com

- Address:

- 1601-1602,A4 Building,Zhujiang Plaza,Longxiang Road,Longgang District , SHENZHEN , GUANGDONG

subscription

QR code

![[MT-700F] Hydraulic Decoiler for Press Feed Sheet Metal Coi Handling](https://icdn.tradew.com/file/201405/1556694/jpg/6842263.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-1300F] Customized heavy duty decoiler machine hydraulic expanion for forming line](https://icdn.tradew.com/file/201405/1556694/jpg/6841693.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-1000F] Hydraulic Decoiler Coil Handling Systems For Press Room Automation](https://icdn.tradew.com/file/201405/1556694/jpg/6842012.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-800F] Motorized Decoiler Machine Hydraulic Expansion Coil Cradle Steel Coil Decoiling](https://icdn.tradew.com/file/201405/1556694/jpg/6841732.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-900F] Hydraulic Decoiler for Sale in Factory Price UK](https://icdn.tradew.com/file/201405/1556694/png/6840509.png?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-1200F] Heavy duty hydraulic uncoiler machine for metal shells stamping process](https://icdn.tradew.com/file/201405/1556694/jpg/6840466.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)

![[MT-600F] Sheet Metal Hydraulic Decoiler Machine for Steel Coil Processing](https://icdn.tradew.com/file/201405/1556694/jpg/6840297.jpg?x-oss-process=image/resize,m_pad,l_120/quality,Q_90)