Home / All / Decoiler Straightener Feeder / GLK2 (0.3-3.2mm) Coil Feeding Line /

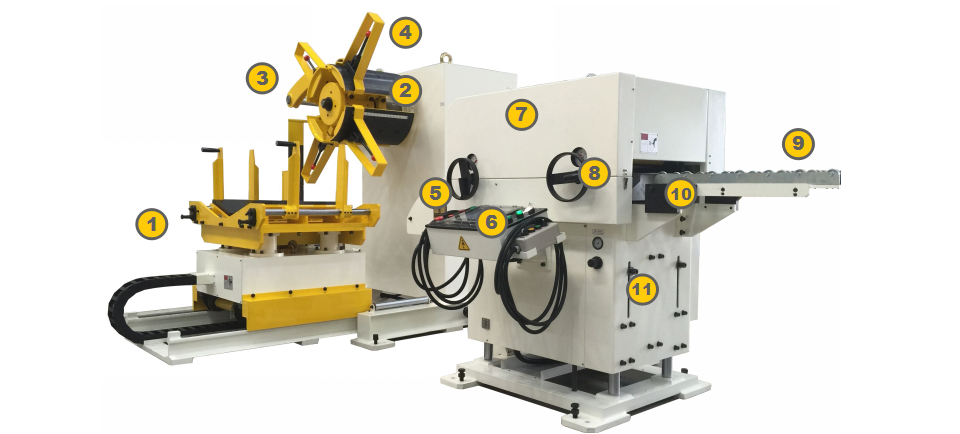

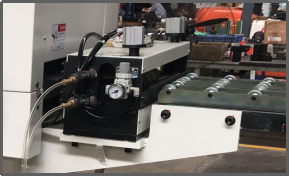

GLK2 Decoiler Straightener Feeder (0.3-3.2mm)

GLK2 Decoiler Straightener Feeder (0.3-3.2mm)

| Categories | GLK2 (0.3-3.2mm) Coil Feeding Line |

|---|---|

| Brand | HongEr |

| Model | GLK2 |

| Applicable material | SPHC.SPHD,SPCC,SPCD,SPCE,Galvanized coil |

| Coiler car | Safe and convenient coil loading operation with the assist |

| Uncoiler shaft synchronizes with feeder machine | Adopting frequency control and gear motor. |

| Power driven pressing arm | prevents the material from being scattered and to assist the uncoiling |

| Uncoilling direction | From bottom to up input coil |

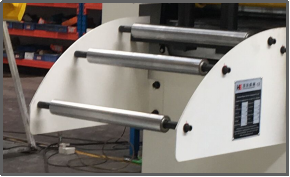

| Straightener roller | Φ48mm x 11 pieces ,top 6/ bottom5, |

| Straightener number adjustment way | Worm adjusting by Manual |

| Straightener roller drive way | Side gear drive |

| Straightening precision | ≤1.5mm/㎡ |

| Feeding line height adjust way | Motor-driven , Feeding line height ±100mm |

| Update Time | Oct 23,2024 |

Detail Information

Product Description

GLK2 DECOILER STRAIGHTENER FEEDER 3 IN 1

Capacities

Coil width: 50mm-500mm

Material thickness: 0.3mm-3.2mm

Coil weight: 3Ton

Line speed: 20m/min

Line length: 3.2m

Material: CR Steel, HR Steel, Stainless, Aluminum, Copper etc.

1. Coil Car

Hydraulic power, wear-resisting surface

2. Decoiler Mandrel

Hydraulic expansion, delta inverter

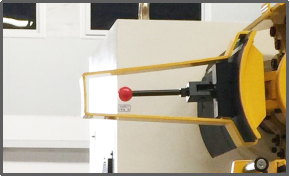

3. Pressing Arm

Coil well-knit, no disperse

4. "A" frame

Locating coil, avoid coil shuffing

5. Coil Inlet

Supporting arm for optional

6. Control Board

Weinview touchscreen

7. Straightening Part

11pcs GCr15 straightener rolls

8. Handwheel

Precision straightening value adjustment

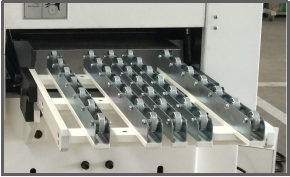

9. Outlet Support Bracket

Adjustable in length

10. Optional Lubrication Unit

Automatic lubrication control, 20L

11. Servo System

Yaskawa servo motor and servo dirve

Specification

Model |

GLK2-400 | GLK2-500 | GLK2-600 |

GLK2-800 | GLK2-1000 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | ||||

Coil Width |

50-400 mm | 50-500 mm | 50-600 mm |

50-800 mm | 50-1000 mm |

Strip Thickness |

0.3-3.2 mm |

||||

Feeding Length | Max. 9999.99 mm | ||||

Coil I.D. | Φ480-Φ520 | ||||

Coil O.D. | Φ1200 | ||||

Loading Capacity | 3000 kgs | 3000 kgs | 5000 kgs | 5000 kgs | 7000 kgs |

Feeding Speed | Max. 20m/min | ||||

Feeding Precision | ±0.1mm | ||||

Straightener Rolls | Φ48mm * 11pcs | Φ68mm * 7pcs | |||

Pinch Rolls | Φ68mm * 2pcs | Φ88mm * 2pcs | |||

Pressing Arm | Pneumatic Type | ||||

Expansion | Hydraulic Expansion | ||||

Uncoiler Motor | 1.5 Kw | 1.5 Kw | 2.2 Kw | 2.2 Kw | 3.7 Kw |

Servo Motor | 2.9 Kw | 2.9 Kw | 2.9 Kw | 4.5 Kw | 5.5 Kw |

* Machine Spec can be customized according to your specific demands.

* Coil Feeding line for high strength material, please check our GLK-H series

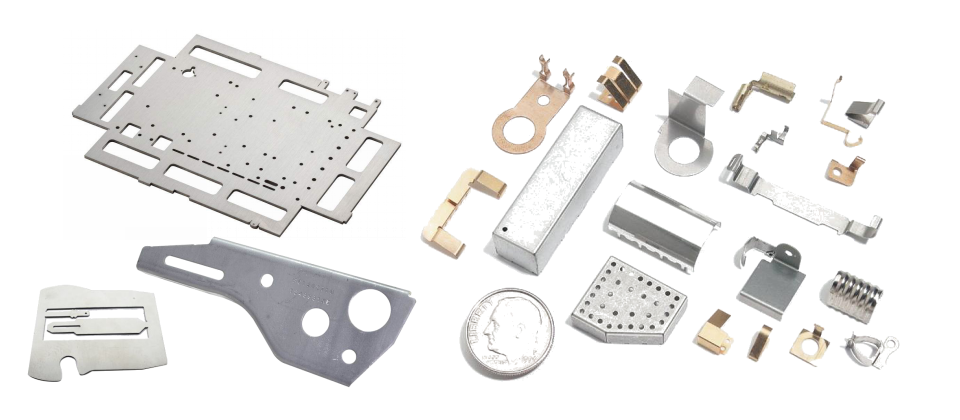

Application

Electronic components, Electrical accessories, Household appliance, Hardware tools

GLK2-500 for LED sheet metal parts manufacturing

Save Workspace!

GLK2-500F, HongEr coil feeding system with AIDA press machine in Vietnam:

Please send your message to us

- Tel

- *Title

- *Content

Send the inquiry, Honger is ready to design the best machine solution for you!

navigation

Contact Person

- Name:

- Fenny Ye

- Tel:

86-755-28372363

86-755-84829280

- Email:

- export@he-machine.com

- Address:

- 1601-1602,A4 Building,Zhujiang Plaza,Longxiang Road,Longgang District , SHENZHEN , GUANGDONG

subscription

QR code