Certificates

What is the role of the feeder pilot releasing device?

What is the role of the feeder pilot releasing device?

Many customers are confused by the pilot release device of the feeder when purchasing the feeders for punch machine. They often asked us what is special about this device. HongEr Machine Equipment answers it here:

The feeder is mainly used with the continuous die of the punching machine to realize automatic high-speed production. The initial feeding accuracy will be very high, but when the multiple feedings accumulate, the cumulative error will be generated, which will affect the precision of the stamping production. At this time, the lifting device on the feeder is needed. It is used with the die guide pin to eliminate this cumulative error. The principle is that each time the feeder feeds (usually feeding in the rising phase of the punch slider), the punch will punch the hole in the material consistent with the guide pin. Down, the tip of the guiding pin is inserted into the material guiding hole, then the loosening device controls the feeder to not clamp (completely loosen the material), and the feeding guide pin is used to correct the feeding error of the feeding machine. Therefore, when the stamping die has a guiding pin, the feeder can be equipped with a relaxing device to correct the error and achieve high-precision feeding; if the die has no guiding pin, the feeder cannot be relaxed.

In order to deepen your understanding of the feeder pilot release device, here are the pilot releasing devices of the three commonly used feeders:

1. The air feeder is equipped with an R-type electromagnetic valve to control the fixed splint for instant relaxation and achieve high-precision feeding. When the mold guiding pin is inserted into the guiding hole, the guiding rod touches the micro switch to generate a relaxation signal, which is transmitted into the R-type electromagnetic valve, so that the fixing plate is instantaneously relaxed.

Note: R type electromagnetic valve requires independent power supply, and there are solenoid valves of 24V, 110V and 220V.

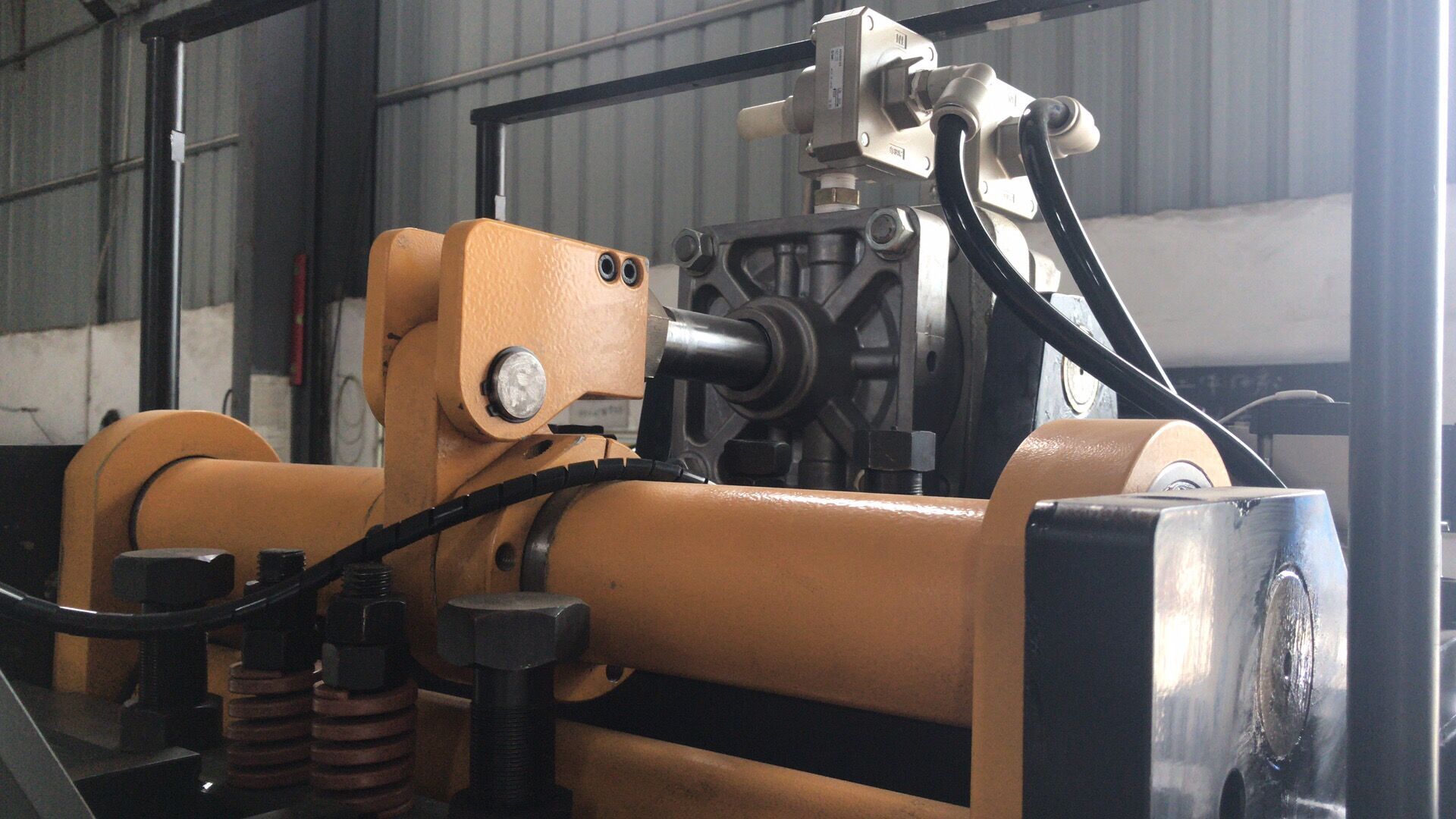

2. The roller feeder is equipped with a pilot release device. The pilot release device is mounted on the punch slider. When the slider is lowered and the tip of the positive guide pin is inserted into the guide hole, the loose screw hits the outer edge of the bearing, so that the passive wheel leaves the material for 0.2-0.5mm, at this time the feeder completely releases the strip to achieve relaxation.

Special attention: the loose screw must touch the outer edge of the bearing to avoid damage to the screw or the bearing seat; the loose bracket must be shaken during the use of the feeder, and the shaking amount must be greater than 0mm, less than 5mm.

3. The NC servo feeder is divided into pneumatic NC and mechanical NC according to the different pilot release devices. Pneumatic NC feeder, pneumatically released, realized by cylinder and electromagnetic valve. The principle of action is similar to that of air feeder. When the tip of the die guide pin enters the guide hole, the punch gives the feeder a releasing signal. The roller rises and completely relaxes the material. The mechanical NC feeder and the roller feeder use the same relaxation device.

About HongEr Machine

Focusing on designing and providing the highest quality coil handling and press feeding equipment, Honger develops with cutting-edge technology and considerate service. From custom designing&engineering to fabrication then to commissioning&training, Honger offers one-stop solution to solve the problem of feeding coil into the press so well and increase production so substantially. Today, Honger is a dedicated enterprise featuring facility manufacturing, modern management, extensive sales network, and ingenious marketing.

Contact Us

For more information and knowledge, please freely contact us now!

Send the inquiry, Honger is ready to design the best machine solution for you!

navigation

Contact Person

- Name:

- Fenny Ye

- Tel:

86-755-28372363

86-755-84829280

- Email:

- export@he-machine.com

- Address:

- 1601-1602,A4 Building,Zhujiang Plaza,Longxiang Road,Longgang District , SHENZHEN , GUANGDONG

subscription

QR code