Home / All / Decoiler Straightener Feeder / GLK-D Straightener-Feeder with Double Decoiler /

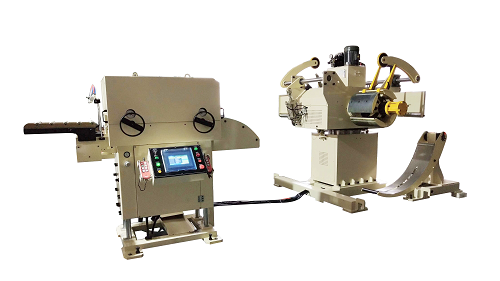

GLK2-D Straightener Feeder with Double Decoiler (0.2-3.2mm)

GLK2-D Straightener Feeder with Double Decoiler (0.2-3.2mm)

| Categories | GLK-D Straightener-Feeder with Double Decoiler |

|---|---|

| Brand | HongEr |

| Model | GLK2-D |

| Applicable material | SPHC.SPHD,SPCC,SPCD,SPCE,Galvanized coil |

| Coil car | Safe and convenient coil loading operation with the assist |

| Uncoiler shaft synchronizes with feeder machine | Adopting frequency control and gear motor. |

| Power driven pressing arm | prevents the material from being scattered and to assist the uncoiling |

| Uncoilling direction | From bottom to up input coil |

| Straightener roller | Φ48mm x 11 pieces ,top 6/ bottom5, |

| Straightener number adjustment way | Worm adjusting by Manual |

| Straightener roller drive way | Side gear drive |

| Straightening precision | ≤1.5mm/㎡ |

| Feeding line height adjust way | Motor-driven , Feeding line height ±100mm |

| Update Time | Jul 27,2024 |

Detail Information

Product Description

GLK2-D STRAIGHTENER FEEDER WITH DOUBLE DECOILER

For GLK2-D series of coil feeding line, a simple panel operation can make coil material loading and strip loop formation automatically.

This is a decoiler straightener feeder with high automation that improves work efficiency.

The double decoiler part can help change the coil convenient and swift.

A wide range of coil specifications can be handled by this coil feeding line, including strip width of 50mm to 1000mm and sheet thickness of 0.3mm to 3.2mm.

This model is designed for coil width an outside diameter up to 1200mm.

The double decoiler design can help change the coil convenient and swift with simple operations.

The strip is drawn off the coil from the bottom.

The coil can be well-knit thanks to a rubber wheel pressing arm, to avoid strip disperse.

4 pcs of "A type frames" can locate the strip, avoid coil shuffling

Hydraulic coil loading car is optional for each customer's specific request.

Strips mounted on the decoiler will be threaded up to the straightener inlet until a loop shape is formed, and this achieves a shorter setup time.

All the straightening rolls HongEr use is GCr15, hardness reaches HRC 58-62, through 100% quality inspection.

Air pressure helps the straightening-feeder improving ease-of-maintenance and performance.

The straightener feeder has a Mitsubishi PLC (programmable logic controller) that provides versatility and meet the requirements from different production.

And there is also the hydraulic shearing unit, the automatic lubricating machine for optional.

Specification

Model |

GLK2-400D | GLK2-500D | GLK2-600D |

GLK2-800D | GLK2-1000D |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | ||||

Coil Width |

50-400 mm | 50-500 mm | 50-600 mm |

50-800 mm | 50-1000 mm |

Strip Thickness |

0.3-3.2 mm |

||||

Feeding Length | Max. 9999.99 mm | ||||

Coil I.D. | Φ480-Φ520 | ||||

Coil O.D. | Φ1200 | ||||

Loading Capacity | 3000 kgs per side | 3000 kgs per side | 5000 kgs per side | 5000 kgs per side | 7000 kgs per side |

Feeding Precision | ±0.1mm | ||||

Straightener Rolls | Φ48mm * 11pcs | Φ68mm * 7pcs | |||

Pinch Rolls | Φ68mm * 2pcs | Φ88mm * 2pcs | |||

Pressing Arm | Pneumatic Type | ||||

Expansion | Hydraulic Expansion | ||||

* Machine Spec can be customized according to your specific demands.

* Coil Feeding line for high strength material, please check our GLK-H series

Application

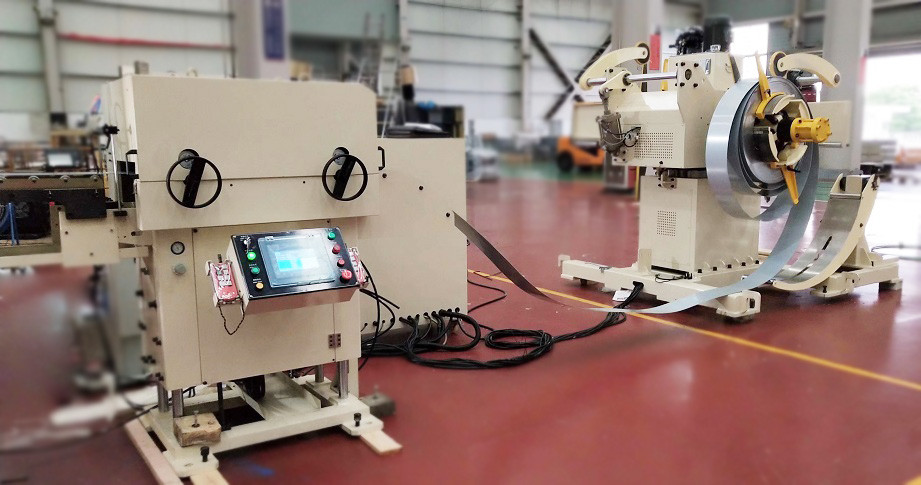

Straightener-Feeder with Double Decoiler in our customer's workshop:

Please send your message to us

- Tel

- *Title

- *Content

Send the inquiry, Honger is ready to design the best machine solution for you!

navigation

Contact Person

- Name:

- Fenny Ye

- Tel:

86-755-28372363

86-755-84829280

- Email:

- export@he-machine.com

- Address:

- 1601-1602,A4 Building,Zhujiang Plaza,Longxiang Road,Longgang District , SHENZHEN , GUANGDONG

subscription

QR code